Faster, more economical – and of the highest quality

Comprehensive practical tests have proven the superiority of the Triflex refurbishment system. This provides you with solutions to refurbish economically and above all sustainably. Transport costs and waiting times at the mixing plant also become a thing of the past, as do residual material disposal costs, since Triflex systems are applied straight out of the bucket.

Further advantages compared to conventional methods:

- No compression work necessary: no damage to adjacent components

- No large-scale equipment such as milling machine, roller or thermo-heating equipment required: reduced personnel and machine expenditure, significantly lower costs

- Final and compressive strength after 30 minutes: faster reopening to traffic and less traffic disruption

- Sustainable environmental compatibility: our products are solvent-free

- Convincing results: satisfied customers who will recommend you to others

Triflex can do more

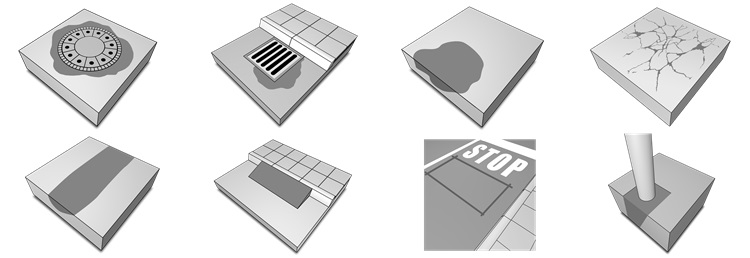

Whether manhole frames or water drains. Whether potholes or broken asphalt edges. Whether cracks, subsidence or ramps: when it comes to maintaining infrastructure, Triflex is the partner to choose.

Filling

| Defects | Joints/cracks | Other |

|

|

|

Adhesive

| Traffic systems | Light signalling | Other structural elements |

|

|

|

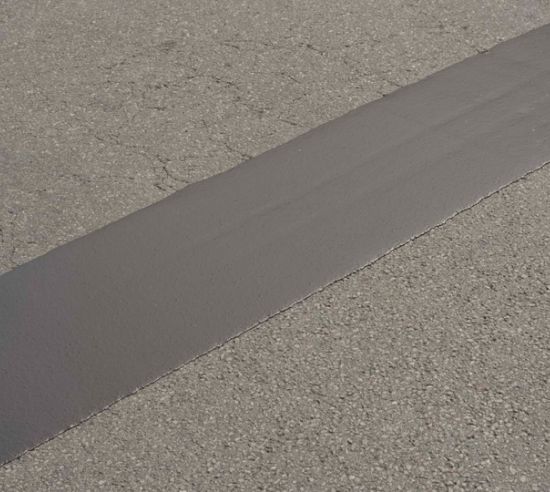

Re-profiling

| Concrete |

|